As more and more companies pursue sustainability initiatives, packaging materials have become top of mind. Businesses spanning from some of the world’s largest brands to personal care startups have started evaluating suppliers with new criteria beyond just price and available inventory.

Now, many companies want to know where the materials will end up and how they’ll affect the environment. When meeting with suppliers, many will ask how compostable their packaging is. But there’s another certification you should also consider: OECD 301B.

Here’s an overview of OECD 301B and how it shows the true life cycle of a packaging material—beyond just compostability.

WHAT IS THE OECD 301B READY BIODEGRADABILITY TEST?

The OECD 301B test method is an international testing method that measures how quickly and effectively a material breaks down when submerged in water under aerobic conditions—that is, in the presence of oxygen.

Biodegradation occurs when a material is decomposed by microorganisms like aerobic bacteria, yeast, and fungi. During this OECD screening test, you simulate how a material would most likely react in an environment like a sewage system.

In the end, the test shows you whether or not a material is “readily biodegradable” or “ultimately biodegradable.”

What Is the Definition of Readily Biodegradable?

According to OECD, a material that’s defined as readily biodegradable has passed several rigorous tests and “will rapidly and completely biodegrade” when exposed to different sources like surface water or sewage effluent (i.e., sewage that’s been treated by a sewage treatment plant).

If the pass level of the test is reached within 28 days, and within 10 days the material achieves 60% biodegradation, the material is considered to be “readily biodegradable.”

If the pass level of the test is reached within 28 days, but not within the 10-day window, then the material is said to be “ultimately biodegradable.”

HOW DOES THE OECD 301B TEST WORK?

Let’s say a lab is testing the biodegradability of a label facestock.

First, they will place 2 to 100 mg/l of the material in at least two flasks or other vessels along with what’s called the “inoculum”—that is, the substance that this material might be exposed to in an aquatic environment.

“The OECD 301B biodegradability test protocol monitors the degree of activity of microorganisms exposed to a material in an aqueous inoculum. If microorganisms recognize the material as a food source, then we can measure the increase in biological activity by assessing the degree of conversion of organic carbon to inorganic carbon.”

— Ashleigh Hotz, Director of Sales, SmartSolve Industries

There are five kinds of inocula sources used for this test method:

- Activated sludge from aeration tank

- Mixture of sources

- Sewage effluent

- Soil extract

- Surface water

Meanwhile, they will fill two other flasks with just the inoculum source, minus the test substance—in this case, the label facestock. These are referred to as “blanks.”

Over 28 days, they will measure how much carbon dioxide is produced by both the test substance and the inoculum. The amount of carbon dioxide produced by both materials will translate to the percentage of biodegradation.

What Results Indicate That a Material Is Readily Biodegradable?

In order to be classified as readily biodegradable, the sample material has to reach a pass level in a 10-day window within the 28-day period of the test. The 10-day window begins when the degree of biodegradation has reached 10% and must end before or at day 28 of the test itself.

Also, the material must reach a biodegradation threshold of 60% or more within 28 days.

WHY OECD 301B MATTERS – AND HOW IT DEMONSTRATES THE TRUE END OF LIFE OF A PACKAGING MATERIAL

We’ve explored what OECD 301B is and what a readily biodegradable material will do within 28 days when exposed to one of the six inocula indicated above. But why is it important?

Where Does Your Packaging Go?

When looking at how “green” a packaging material is, you might be tempted to just assess if it’s recyclable. Still, that’s just the beginning. You need to focus on the final end of a product’s life cycle. What happens after the material is tossed by a consumer? What’s the last place it could go?

If a material is recyclable, there’s a good chance it may still end up in the garbage. Most people don’t recycle correctly. Also, not all municipalities offer recycling services for businesses or homeowners, so recycling isn’t as easy or convenient—and thus, can occur less frequently.

Besides, if a packaging material is made of plastic, it’s much less likely to be recyclable. Plus, a recent study showed that 91% of plastic in the world isn’t recycled. Instead, it can often turn up in places it shouldn’t be, like our water sources.

Why You Need to Go Beyond Recycling

So, even if a material is recyclable, if it’s made of a plastic or another material that takes a long time to degrade, it could still hurt the environment. That’s why using tests like OECD 301B can show what a material will do if it ends up in an aerobic environment.

If a material is found to be readily biodegradable, you’ll know that it will break down quickly in its final resting place and revert to its natural state.

COMPOSTABLE VS. BIODEGRADABLE: HOW ASTM D6400 DIFFERS FROM OECD 301B

Many sustainable-savvy companies have caught on to the importance of tracing the life cycle of a material and look for packaging that has little to no impact on the environment—even if it ends up in our waterways. They then start to gauge if the material is compostable, often asking about one specific standard: ASTM D6400.

This American standard measures how compostable a product is that’s made of plastic. ASTM D6400 is important in its own right, but OECD 301B offers more—especially if you’re looking at solutions that incorporate bio-based content. Here’s how.

OECD 301B Shows the Rate of Biodegradability of a Material

“[ASTM D6400] is not a single method, but a combination of individual tests that looks at bio-based content, bio disintegration, biodegradation, and toxicity to plants. Per this method, the material is incubated at 50 degrees centigrade for 90 to 180 days, making the test method somewhat selective for bacterial-based biodegradation. Because of the higher temperatures and times used, a material that passes this test may not degrade under natural conditions.”

— Jonathan Jakubowski, Director, SmartSolve Industries

The OECD 301B method gives a direct report on the ability of the material to break down under natural conditions if released to the environment. It’s a very convenient method when studying water-soluble materials, for example.

Conducted at 25°C, this test is considered to have very stringent conditions for this type of process, which is why this is the preferred method to determine the biodegradability of chemical substances in general.

This is the main reason why we had some of our technologies tested using the OECD 301B method—all of which were found to be readily biodegradable.

ASTM D6400 Doesn’t Demonstrate Biodegradability

Consequently, even if a plastic material is found to be compostable, it may not be biodegradable. That’s why evaluating whether or not a material has passed the OECD 301B test is worth exploring.

What’s more, if you’re looking at materials that aren’t plastic-based, ASTM D6400 won’t even be relevant.

WHAT SMARTSOLVE MATERIALS ARE READILY BIODEGRADABLE?

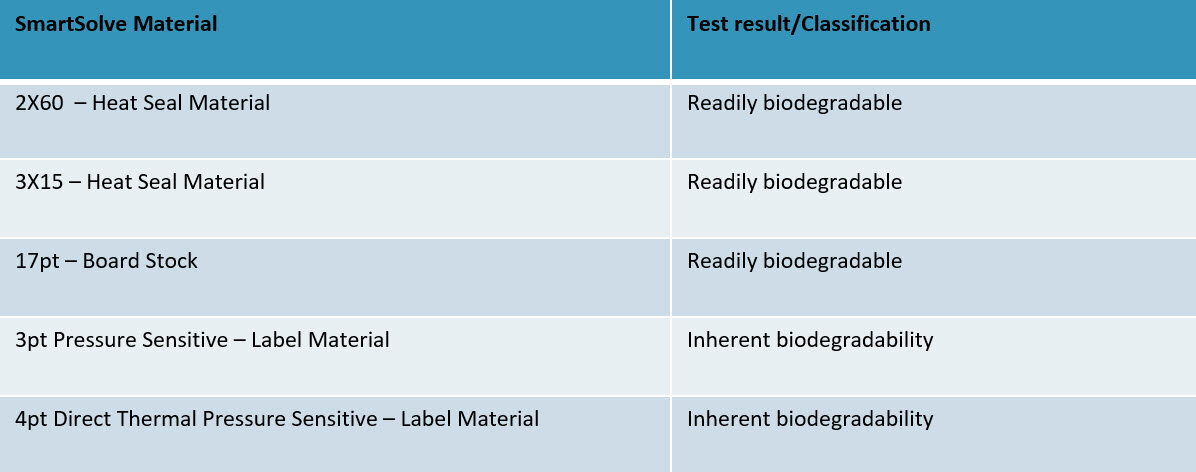

SmartSolve materials have undergone extensive third-party testing, especially concerning biodegradation. Below is a chart of our materials that have the OECD 301B classifications of Readily or Inherent.

WHAT ARE SOME OTHER SUSTAINABILITY INITIATIVES TO LOOK INTO?

Besides looking at how readily biodegradable your packaging material could be, there are many other ways to pursue sustainability at your company. Check out our other blog articles below for more advice:

- How To Promote Environmental Sustainability Within Your Company

- 7 Ways Your Company Can Reduce Packaging Waste